In the ever-changing landscape of steel construction, accuracy and efficiency are paramount. At 4 Summit, we’ve witnessed and adapted to significant shifts in how we approach project planning and execution. Today, we’re exploring our journey from traditional surveying methods to the increasing adoption of 3D scanning technology.

The Foundation: Traditional Methods

For years, the cornerstone of our planning process has been the use of detailed drawings. We typically request these in DWG or PDF format, with a preference for DWG files due to their creation in specialised detailing software, which often ensures a high degree of accuracy. For smaller projects where DWG files aren’t available, we’ve developed workarounds, such as importing PDFs into our modeling software and scaling them using provided dimensions or on-site measurements.

New builds present a straightforward scenario. We expect and work from DWG files provided by the design team, which typically eliminates the need for additional site dimensions and ensures 100% accuracy across all parties involved in the project.

The Challenge of Existing Structures

However, when dealing with existing buildings, the landscape becomes more complex. Even when provided with DWG or PDF files, their accuracy can’t be guaranteed unless a comprehensive survey, such as a 3D scan, was performed during the initial assessment. In these cases, our team takes matters into their own hands.

Our surveyors conduct thorough on-site measurements. This process involves:

1. Taking wall-to-wall dimensions

2. Drawing detailed sections (e.g., roof detail elevations showing connections between timber rafters and brick walls)

3. Recording critical levels for joists and concrete surfaces where our columns will be fixed

This meticulous approach ensures we have accurate heights for our steelwork and a comprehensive understanding of the existing structure.

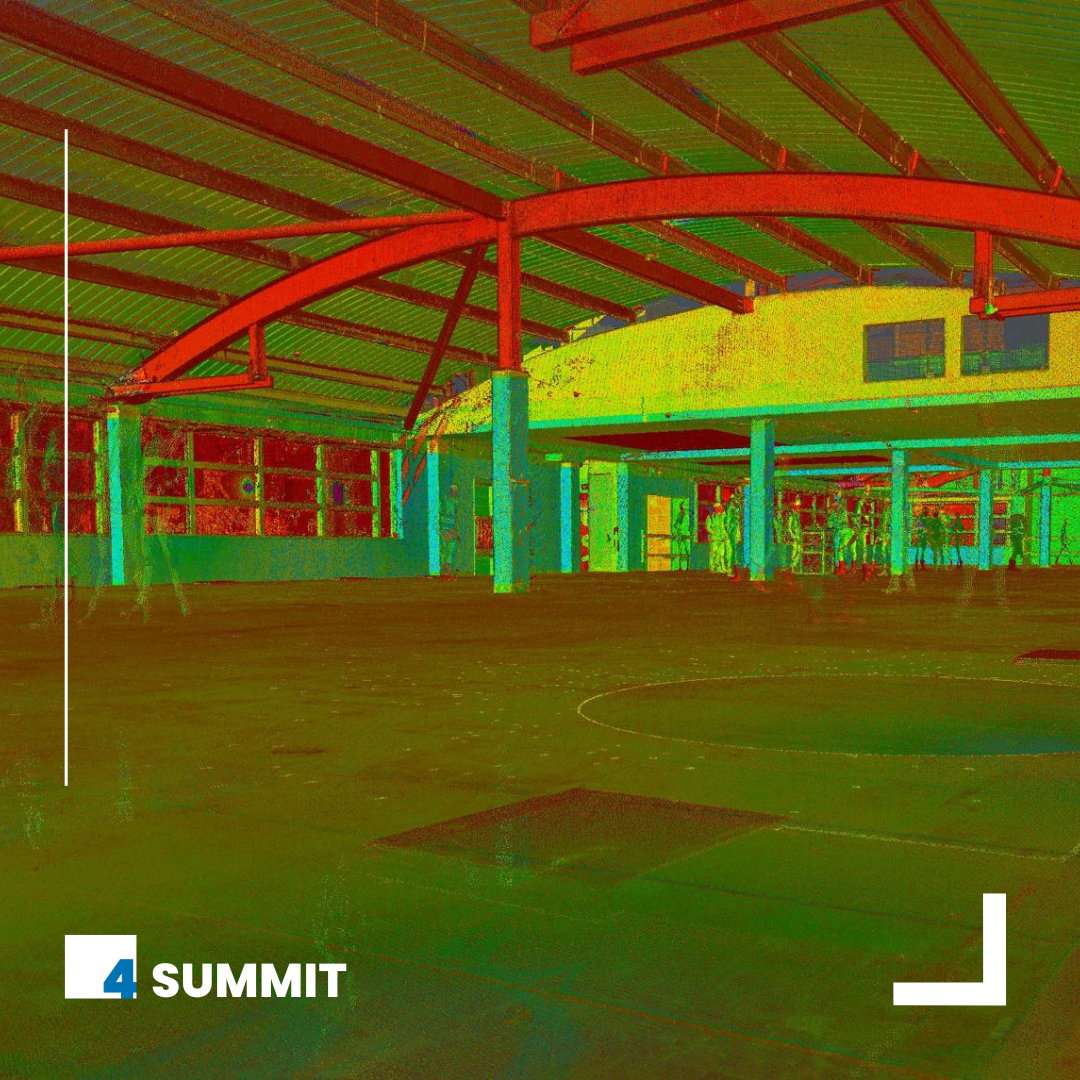

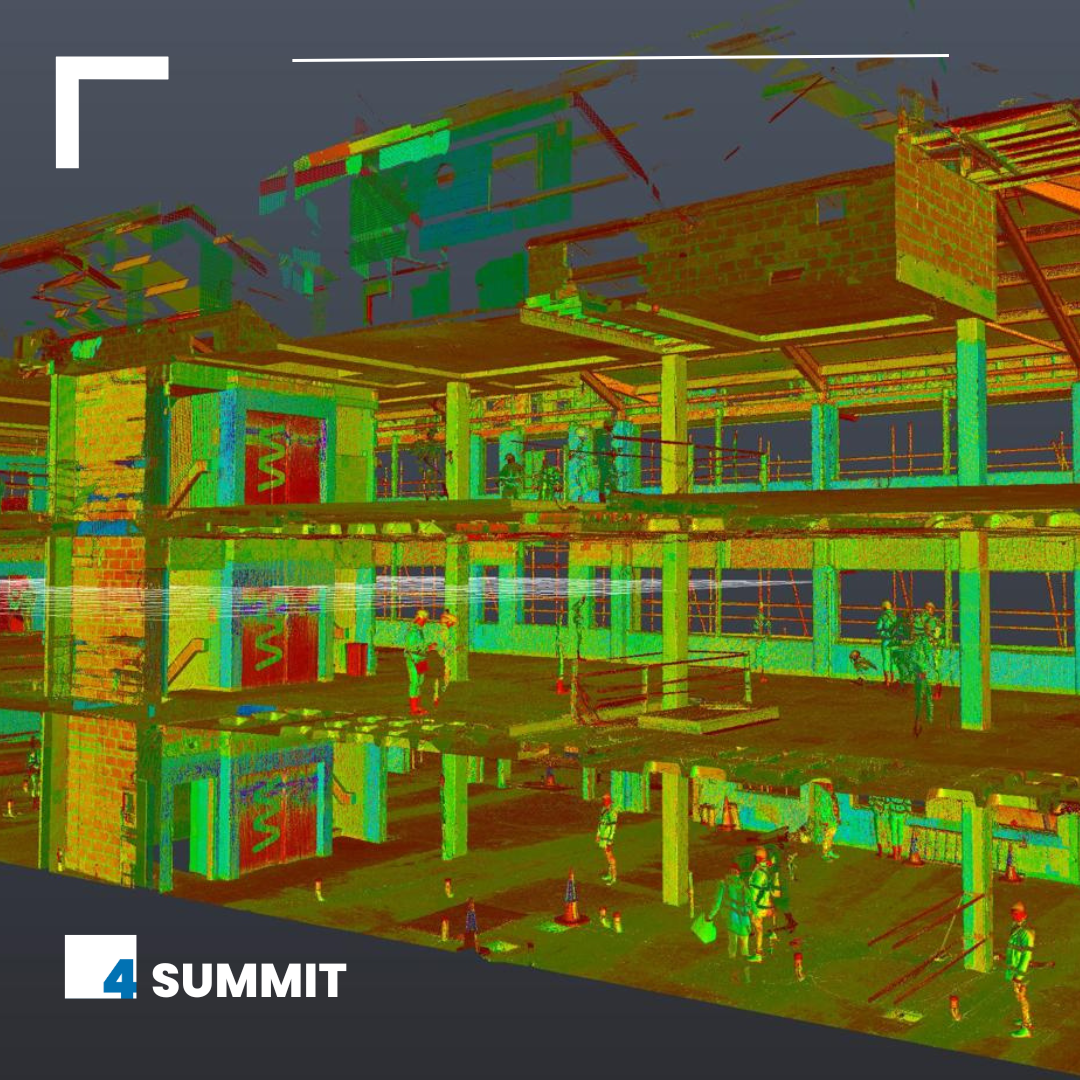

The Rise of 3D Scanning

Over the past three years, we’ve seen a significant shift in our approach to surveying, particularly for more complex projects. As 4 Summit has grown, we’ve taken on larger projects in existing buildings with numerous steel elements. These projects posed a challenge: traditional surveying methods were becoming increasingly time-consuming, often requiring multiple site visits for additional measurements. To meet this growing demand for precision and efficiency, we have recently begun outsourcing our 3D scan requirements to ASES Limited, a trusted partner in advanced surveying technology. This is where 3D scanning has become a game-changer. When I began detailing three years ago, we used 3D scans occasionally. However, as our company has expanded and the complexity of our projects has increased, we’ve found ourselves turning to this technology more frequently.

The Benefits of 3D Scanning

1. Comprehensive Data Collection: A single 3D scan captures all necessary details from the start, eliminating the need for return visits.

2. Time Efficiency: Especially crucial for larger projects, 3D scans significantly reduce the time spent on site surveys.

3. Accuracy: 3D scans provide highly precise measurements, reducing the risk of errors in the planning and fabrication stages.

4. Accessibility: Scans can capture data from hard-to-reach areas that might be challenging or unsafe to measure manually.

When 3D Scanning is Essential

The need for 3D scans is project-specific. We find them particularly valuable for:

1. Structures with complex geometries

2. Projects where multiple steel elements interact with existing architecture

3. Situations where repeated site visits would be impractical or costly

The Future of Surveying at 4 Summit

As we continue to grow and take on more complex projects, the role of 3D scanning in our workflow is likely to expand. Two years ago, we might have had only one or two projects that benefited from this technology. Today, with our increased capacity and project complexity, the efficiency and accuracy offered by 3D scans have become indispensable for many of our larger undertakings.

However, we maintain a flexible approach. For smaller projects or new builds where accurate DWG files are available, traditional methods remain effective. Our goal is to use the right tool for each job, balancing cutting-edge technology with tried-and-true methods to deliver the best results for our clients.

Conclusion

The evolution of surveying methods in steel construction reflects the industry’s broader trend towards digitalisation and precision. At 4 Summit, we’re proud to be at the forefront of this change, adopting new technologies like 3D scanning while maintaining our expertise in traditional methods. This balanced approach allows us to tackle projects of all sizes and complexities, ensuring accuracy, efficiency, and quality in every steel structure we create.

As we look to the future, we remain committed to innovation, always seeking ways to enhance our processes and deliver exceptional results for our clients. Whether through advanced 3D scanning or meticulous manual measurements, our focus remains unwavering: to provide the highest quality steel solutions for every project we undertake.

Ready to transform your next steel construction project with cutting-edge 3D scanning technology? Contact our team today to discuss how we can bring precision and efficiency to your build. Let’s turn your vision into reality with the power of advanced surveying methods.

Related posts

Forging the Future: How We're Revolutionising Steel Fabrication, Supply, and Installation with Digital Innovation

[ READ ARTICLE ]

Enhancing Steel Construction: The Critical Role of Thermal Breaks

[ READ ARTICLE ]

4 Summit in premier construction magazine

[ READ ARTICLE ]

Why Is Steel Used In Construction?

[ READ ARTICLE ]

What Is Steelwork Used For?

[ READ ARTICLE ]

Precision grinding is used for materials.

[ READ ARTICLE ]